Lean Six Sigma in Manufacturing, Lean Six Sigma in Service Industries

DMAIC Project – Reducing Future Property Claims for a Client in the Ski and Snowboard Industry

Company:

EPIC Ski and Snowboard Company builds high end skis and snowboards for their own brand as well as OEM for other industry brands.

Problem:

EPIC had filed an insurance claim caused by a 55-gallon drum of epoxy leaking onto the factory floor causing a quarter million dollars in damage to product and equipment. The adjustor needed to identify the cause of the damage and determine whether the scenario was covered by EPIC’s policy. Both parties also hoped to reduce the risk of future damage and claims.

Solution:

The claims adjustor worked with the EPIC management team and, using the Lean Six Sigma DMAIC (Define, Measure, Analyze, Improve, Control) methodology, identified the root cause of the problem. The EPIC team and adjuster worked together to implement new process controls that would prevent this type of damage in the future.

Define:

The team defined the problem as “Employees continue to make mistakes with dangerous and expensive equipment and materials resulting in over $500k in costly cleanup, damaged raw materials, and damaged equipment in the past year.” The customer and stakeholders in this project were identified as the EPIC company and EPIC’s insurance carrier.

Measure:

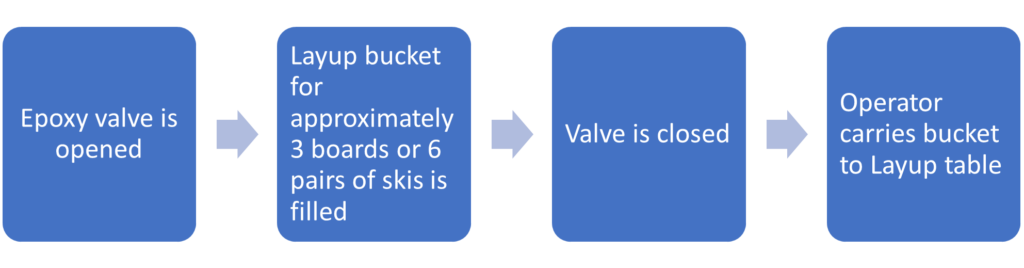

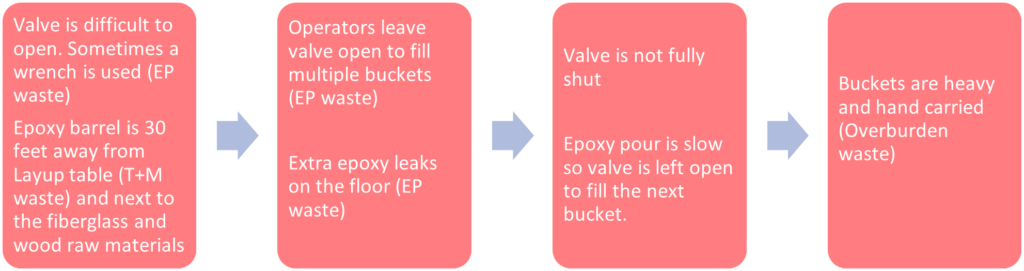

The team used a Value Stream Map to walk through the current state process and collected data from the employees.

Analyze:

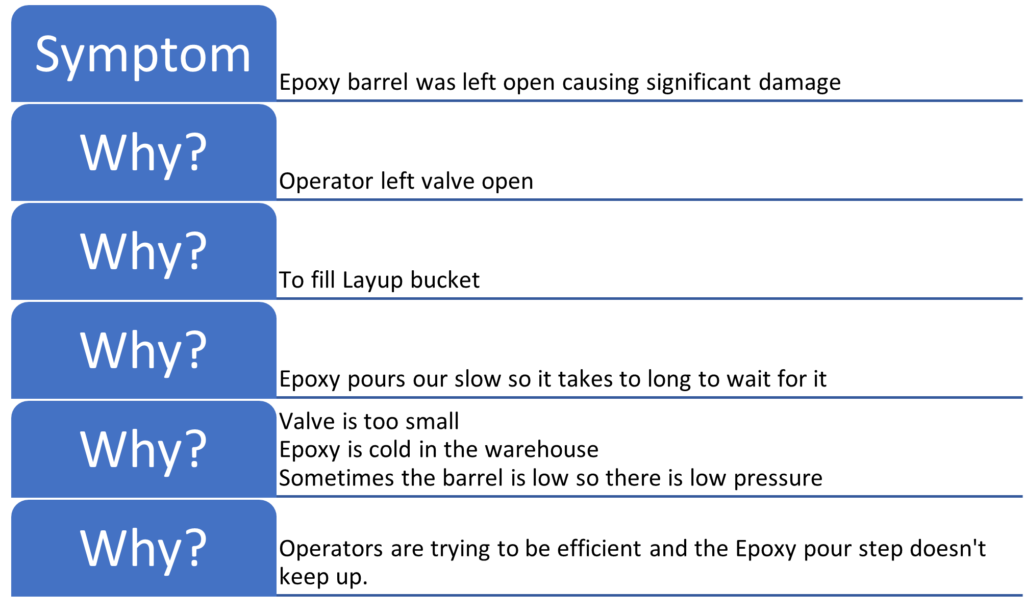

EPIC and the adjustor performed a 5 Whys root cause analysis.

The 5 Whys analysis revealed that employee frustration with the speed of the pour valve was the primary root cause. Leaving the valve open could be fixed with training and visual reminders but that would not be 100% mistake proof and would not solve the speed problems faced by the operators.

The claims adjustor found the root cause to be Human Error. Review of the policy showed that the fact that the problem was caused by human error did not vitiate the policy. The case was covered with for the following amounts.

- $60,000 wood cores

- $35,000 fiberglass

- $38,000 resin

- $23,000 art and base

- $90,000 equipment

Improve:

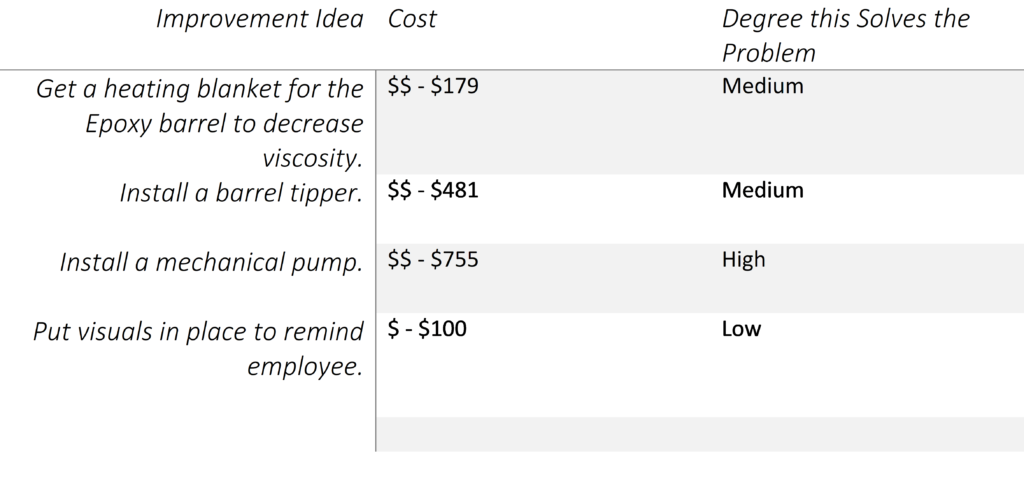

The team came up with a list of countermeasures that could eliminate future mistakes.

After comparing each solution the team decided to go with a mechanical pump and a heating element. This would keep the epoxy fluid and allow the operator to quickly fill the Layup bucket without the chance of leaving the valve open.

Control:

The team implemented control measures to ensure that the improvements were sustained over time including,

- Updated Work Instructions

- Automated Power Box to turn off heater at 6pm and back on at 7am prior to shift start at 7:30

- Trained operators to use the new pump

The team continues to track the epoxy usage per quantity produced and expects this metric to go down with the new pump as less material is wasted.

Results:

Following the process improvements the team experienced zero spills for 3 months. The estimated cost savings were $40,000 in epoxy plus a cost avoidance of $500,000 based on the amount filed to the insurance company in Q1.

Conclusion:

By working together, EPIC and the 3rd party claims adjustor were able to identify the root cause of the problem and come up with a solution that would prevent further property claims. This also created a safer work environment for the employees.