Certification for Lean Six Sigma in Healthcare Management

In the last decade, healthcare has undergone a complete transformation by using the principles and tools of Lean Six Sigma. Teams of nurses, doctors, and care providers are gathering data, mapping their processes, and performing root cause analysis to solve complex problems and improve patient care.

Creating a Lean Culture

Creating a Lean Culture in your hospital or clinic takes planning, hard work, and skill but the end results are worth it! At Lean Six Sigma Toolbox we often start with a specific project in one department such as:

- Reducing LOS (Length of Stay) in the Emergency Department

- Improving patient satisfaction in Med Surg (care and recovery)

- Reducing turnaround times in the Lab

…then leverage these wins to increase awareness and adoption of Continuous Improvement in other areas of the hospital.

The case study below shows how we helped a hospital use the Lean Six Sigma DMAIC process to reduce the length of stay for patients in their Emergency Department. This dramatically improved patient satisfaction and reduced stress on the ED staff.

This case study was part of the Hospital’s initiative to train its leaders in Lean Six Sigma and receive their Lean Six Sigma certification. This supported the hospital’s long-term goal to improve patient outcomes and employee satisfaction by creating a culture of Continuous Improvement. Through this project and others like it in Radiology, Med Surg, Rehab Clinic, the Lab, and even the Cafeteria this hospital was able to make significant improvements that resulted in better patient outcomes and satisfaction.

Case Study: Using Lean Six Sigma in Healthcare to Reduce Patient Length of Stay in the Emergency Department

Step 1: Define the Problem

The nurses say we need to build a new, bigger, Emergency Department.

Phil Eaton, CEO, Mountain West Medical Center

When Phil, the CEO of a regional hospital, told me they were considering adding a new wing with 10 or more beds to his Emergency Department… he looked concerned. It was going to be expensive. And while the surrounding communities were growing rapidly he wasn’t sure it was necessary.

The feedback from the ED docs and nurses was clear. There are too many days when we are overcrowded and don’t have room for patients.

The team is ready, let’s improve!

Step 2: Measure the Process and Gather Data

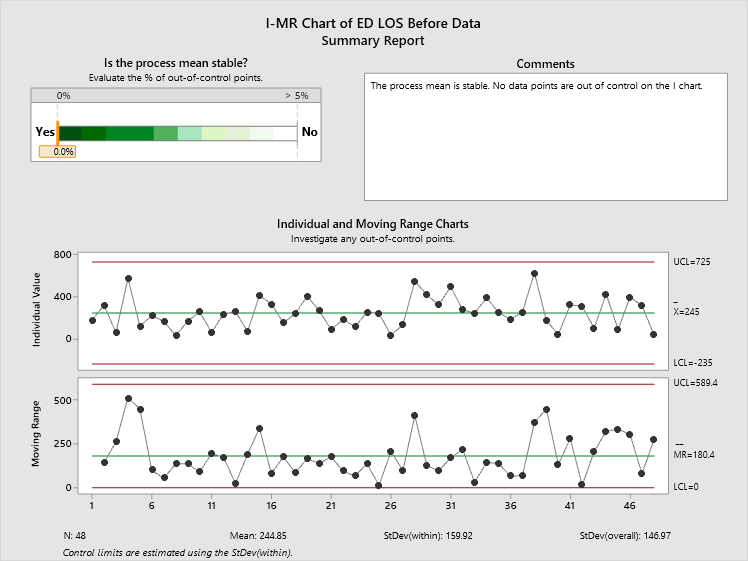

After meeting with the ED Director, Scott, we agreed to gather some data. We tracked the LOS (Length of Stay) for each patient through the ED. I explained Little’s Law and the fact that long cycle times would increase the number of patients in the ED and could be the root cause of the problem.

Now we had data! But what is the goal and how were we performing against it?

“A 5 star hospital should process patients through the Emergency Department in 120 minutes (2 hours) or less.”

To understand how well the ED was performing we needed a process capability chart.

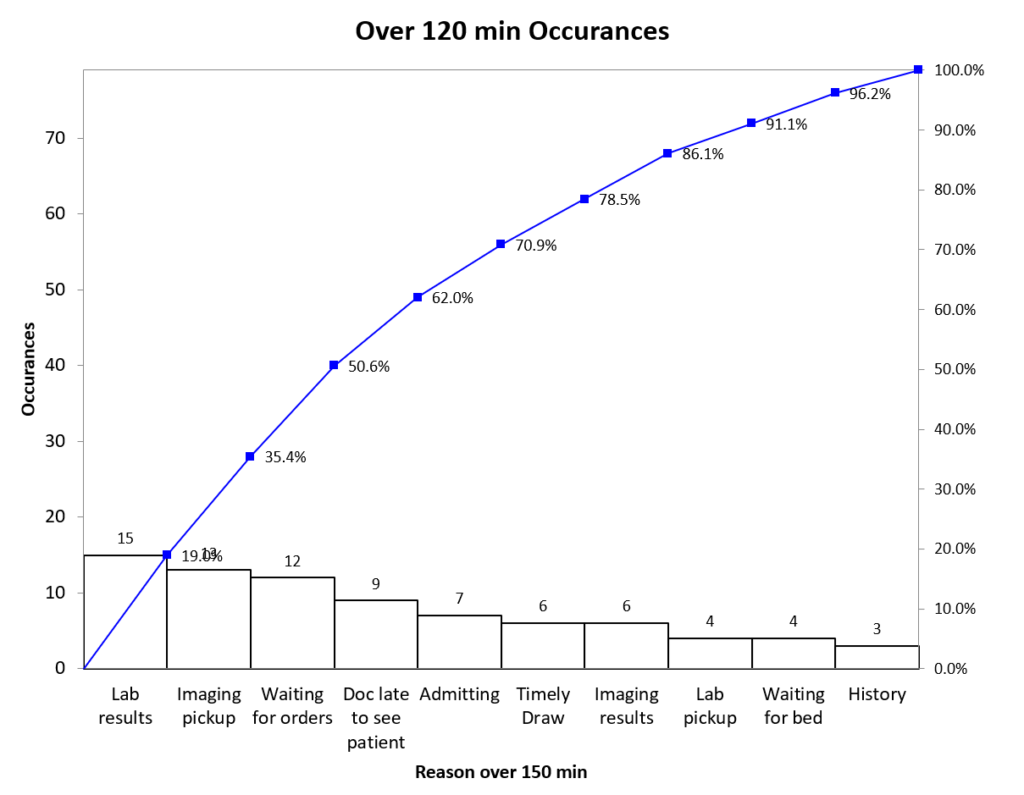

Wow. 46% of our patients were staying longer than 150 minutes or 1 and 1/2 hours. What could be the cause? We needed to find the reason patients were staying over 120 minutes so we implemented a tick sheet.

Step 3: Analyze the Data and Find the Root Cause

This data was eye-opening. We didn’t identify one silver bullet but rather several processes that needed to be improved to reduce our Length of Stay. Most of the delays were caused by hand-offs between the ED and the lab or ED and radiology.

Step 4: Improve the Process… Kaizen!

Armed with this data we kicked off a series of Kaizen Events (rapid process improvement projects). Working with teams from the lab, imaging, and the docs, we found several creative ways to improve communication and reduce delays.

- Improve patient pickup time from ED to RAD

- Reduce delays in draw pick up and drop off from the LAB

- Improve visibility of DOOR to DOC and total LOS in progress

- Simplify the patient admission process

Step 5: Control the Process and Show Results

- Patients love their new, faster, local Emergency Department at Mountain West Medical Center! There’s never a wait and they know they will get the best care without the wait.

- We reduced the average Length of Stay from 185 to 150 minutes within a month then continued to work on projects until the average LOS was well under 110 minutes.

- The hospital has been operating with the same number of beds for over 3 years now and never has overflowed.

- No need for a multi-million dollar expansion.

- ED nurses and docs are happier.

- The communication and relationship between ED – Radiology and ED – Lab improved.

Will Lean Six Sigma work for us?

Yes! We have implemented Lean Six Sigma in healthcare organizations like hospitals and clinics just like yours. Because of our global clientele, it is likely we’ve worked on problems similar to what you are seeing, before. We are not “trainers” but practitioners who focus on getting measurable results within just a few weeks.

Here are the 2 best ways to get started.

- Onsite Lean Six Sigma Green Belt Training + Boost

- This program kicks off multiple projects in your company, each yielding a significant payback

- We come to your facility, training leaders and team members in Lean Six Sigma tools and principles

- Teams select and complete meaningful projects that are aligned with your goals

- Project teams are coached every step of the process so their first experience using Lean Six Sigma is a good one

- Teams report out on their projects giving total savings ($10k to $100k+ per project is typical), as well as improvements to quality, employee, and customer satisfaction

- Kaizen System Implementation

- This program helps individual departments set up a system for Continuous Improvement making Kaizen a part of their culture

- We come onsite and help leaders identify KPIs (Key Performance Indicators) and set goals

- Together teams establish routines including daily huddles and data analysis while creating standard work for critical processes

- Finally, teams kick off a series of small projects using the Kaizen System to address waste and variation discovered through their daily Kaizen routine

When projects are completed, celebrate success!

Implementing Lean Six Sigma in Healthcare

If you are interested in creating a culture of Continuous Improvement in your hospital or clinic, call us! Let’s discuss your needs and how we can help you reach your goals this year.

Additional Resources

- Link to purchase Kaizen Idea Cards for your team.

- Link to whitepaper, “Going Lean in Healthcare“.

Certification for Lean Six Sigma in Healthcare Management

Find out how our Lean Six Sigma in healthcare certification can help you improve patient care and streamline costs. Learn more.

A Better Way to Do Healthcare Management

As a healthcare provider, you want to ensure that you are providing your patients with the best possible care while meeting the needs of your staff. Our Lean Six Sigma framework can give you the tools you need to do just that.

Lean Six Sigma is a widely recognized methodology. It has proven to be effective in improving the quality and efficiency of healthcare services.

Our certification for Lean Six Sigma in healthcare provides healthcare professionals with the skills and knowledge needed to apply this methodology to their work. This ultimately leads to better patient outcomes and more efficient healthcare delivery.

If you are ready to help more patients, contact us today to find out how to enroll in our online program.

What Is Lean Six Sigma in Healthcare?

Lean Six Sigma is a data-driven approach to management. It focuses on minimizing waste, reducing variability, and improving overall quality. This approach combines two methodologies.

These methodologies include Lean, which focuses on eliminating waste and increasing efficiency. It also includes Six Sigma, which focuses on reducing defects and improving quality.

By applying Lean Six Sigma principles to healthcare, healthcare professionals can streamline processes. They can also reduce errors and improve patient satisfaction.

What Our Lean Six Sigma Certification Includes

Our certification includes everything you need to apply this methodology to your healthcare practice facility. It provides you with coursework in Lean Six Sigma methodology, statistics, and data analysis.

It also includes hands-on training in applying Lean Six Sigma principles to healthcare settings. We offer several different levels of training, including:

- Lean Six Sigma yellow belt certification

- Lean Six Sigma green belt certification

- Lean Six Sigma black belt certification

- Lean Six Sigma black belt certification

Why Choose a Lean Six Sigma Approach to Healthcare

Our Lean Six Sigma approach to technology helps healthcare providers do more with the resources they have. Some of the benefits of our Lean Six Sigma training include:

- Better patient care, improved patient satisfaction, and reduced hospital readmissions

- Lower costs to both patients and providers

- Enhanced employee engagement and job satisfaction, as well as improved teamwork

- Better regulatory compliance and reduced liability

These are just some ways implementing our training can help your healthcare organization. Contact us today to learn more, or read our case study below.

Why Choose Lean Six Sigma Toolbox?

At Lean Six Sigma Toolbox, we are proud to be a globally recognized leader in Lean Six Sigma certification and training. We’ve helped more than 426 clients across fifteen different companies.

These companies have been able to improve organizational efficiency. They have also been able to improve relations with the people they serve. Contact us today to learn more about our commitment to your team.

Get Your Lean Six Sigma Certification for Healthcare Today

Lean Six Sigma in healthcare can be instrumental in improving patient outcomes while reducing the workload on your staff. Sign up for our Lean healthcare certification today.