Green Belt Certification in Utah – September 22, 2022 in Lehi

$2,499.00

This is a live, 1-day Lean Six Sigma Green Belt training event in Lehi, Utah followed by self-paced online learning with over 45 modules resulting in a Lean Six Sigma Green Belt certification.

Lean Six Sigma Green Belt is the most useful of the Lean Six Sigma belts. Training your managers, supervisors, and engineers will create a culture of Continuous Improvement that will pay dividends for years to come. Green Belts are placed into teams and required to complete a process improvement project. Teams save over $20,000 on average for their companies by improving Key Performance Indicators such as throughput, quality, profitability, and employee morale.

The Lean Six Sigma Green Belt course includes:

- 40 hours of instruction

- $299 SigmaXL statistics software

- Green Belt Exam

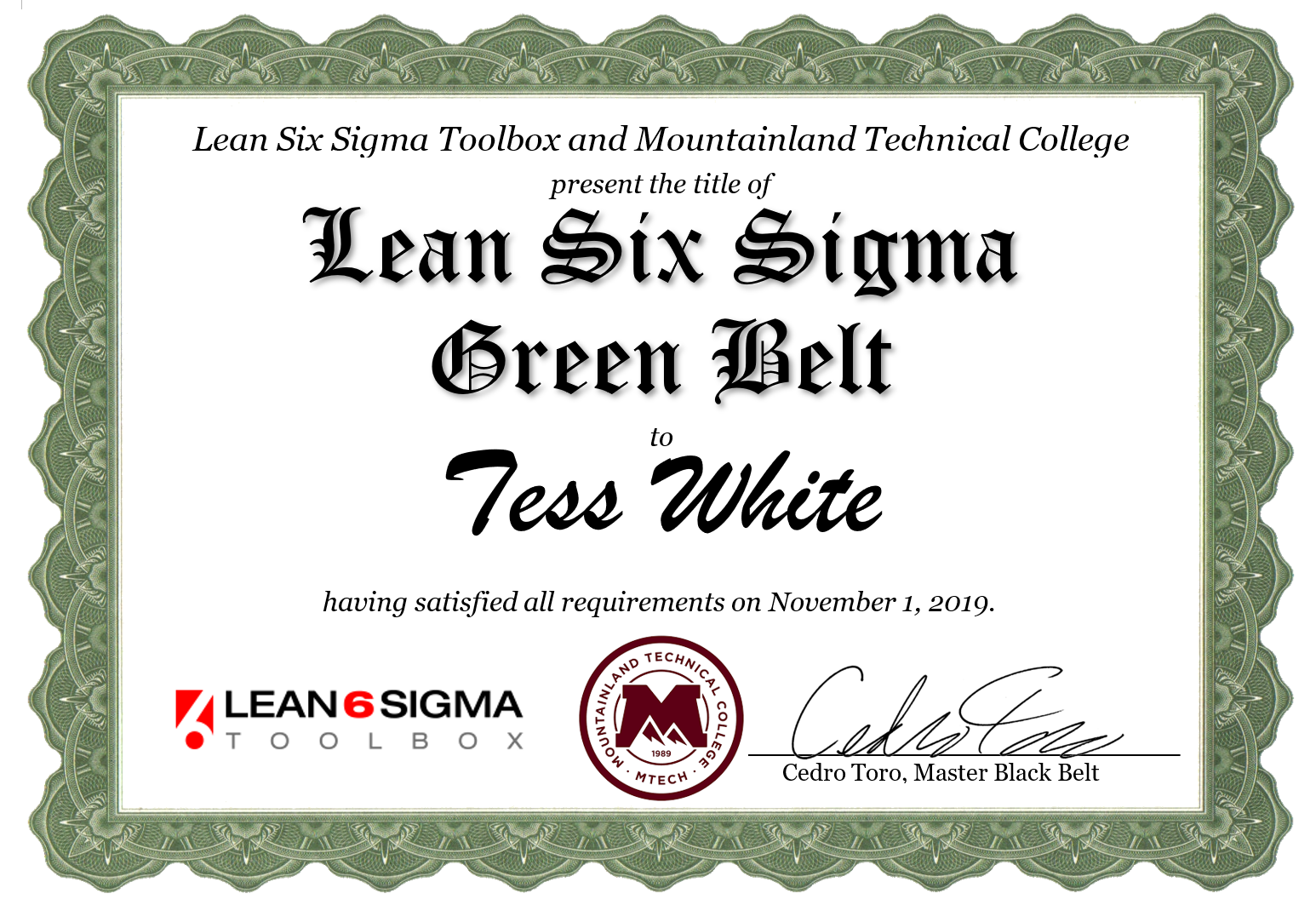

- Globally Recognized Framed Certificate

- 1-on-1 coaching while completing the required Green Belt process improvement project

Register your team today.

Upcoming Lean Six Sigma Green Belt Certification in Utah

Training your team in Lean Six Sigma is the first step in creating a culture of Continuous Improvement that will pay dividends for years to come. In the upcoming Lean Six Sigma Green Belt course, your team will learn to eliminate waste and improve Key Performance Indicators such as throughput, quality, profitability, and employee morale.

Training your team in Lean Six Sigma is the first step in creating a culture of Continuous Improvement that will pay dividends for years to come. In the upcoming Lean Six Sigma Green Belt course, your team will learn to eliminate waste and improve Key Performance Indicators such as throughput, quality, profitability, and employee morale.

This is a blended course where students can attend the live training Thursday, September 22nd after which classes will be held online.

Who should attend?

Green Belt Certification is for supervisors, department leaders, quality and engineering teams, and any team member in your company who wants to lead projects that deliver measurable results in their key performance indicators! Green Belts are project leaders with a solid working knowledge of methods to improve throughput, quality, and lower costs.

How does the company benefit?

Green Belt candidates are required to complete a process improvement project as part of their course work that provides a significant ROI to the company. Graduates regularly save their companies over $100,000 through their required Green Belt projects. On average teams save $22k per project.

What will students learn?

Students learn tools and techniques including:

- 8 Wastes

- Kaizen Events

- DMAIC Projects

- Advanced Root Cause Analysis

- Statistical Process Control

- Creating Flow

- Building Quality Into the Process

Can’t make the live sessions? Register for the 100% Online Self-Paced Green Belt here.

What are the certification requirements?

To obtain Green Belt Certification students must:

- Complete training courses

- Complete Green Belt exam

- Complete a Project or Kaizen Event with validated savings within 90 days

- Students are encouraged to organize in teams of 2 but no more than 3 to complete a process improvement project in their area.

- Upon certification, students are encouraged to maintain their skills by completing at least 2 continuous improvement projects per year throughout their careers.

How do students attend class?

This is a blended course. Green Belts will attend 1 day of in-person training in Lehi Utah. Following this students will complete the training modules online while attending 1-on-1 coaching sessions with an assigned Lean Six Sigma Master Black Belt to complete their required project. training modules can be delivered in 3 different formats:

- Training Session 1: In-Person Lean 101 Six Sigma Yellow Belt with Simulation Location: Lehi UT

- Training Sessions 2-5: 100% Online Self-Paced Learning

Watch over 45 training modules using our online LMS (learning management system). Students can learn from their phone or computer at their own pace anytime, anywhere. Students still get 1-on-1 coaching and support to help them complete their Green Belt Exam and Project. This method is perfect for teams with multiple shifts who cannot commit to live training. - Project Timeline & Coaching

Students are given 8 weeks starting their first week of training to work on a process improvement project. During this time they will meet weekly with their Lean Coach to complete project milestones. - Exam

Don’t stress! Students can complete and submit their exam online or attend the exam review day where we will walk students through the exam one question at a time. - Report Out

Students will meet for a 1/2 day report out and celebration at the end of the 8 weeks.

What resources are provided with the class?

Each student will receive:

- 40 Training Modules

- Over 26 tools, templates, and exercises

- A certified Lean Coach to assist each Green Belt team with their project

- Framed Green Belt Certificate upon project completion

Is there software required?

Green Belt candidates will be expected to have access to:

- Microsoft Excel or similar

- Microsoft PowerPoint or similar

- SigmaXL statistical software is included with this training

Do students receive a certificate?

Yes! Upon completion of the course requirements, students will receive a globally recognized and framed Lean Six Sigma Green Belt certificate.

What is our company’s return on investment?

By following the principles taught and completing projects, clients typically experience over a 10X return on investment with average project savings exceeding $20,000 and many exceeding $100,000. We will work with your team to set specific targets for project outcomes and KPI improvements.

What is expected from the students and organization?

Green Belt students will commit to:

- Attend each training session (or view sessions online) and internalize the materials.

- For live classes, this will likely require changing work schedules and delegating work to others on your team.

- Complete project assignments so that the Green Belt project can be completed in 90 days. Project teams must implement lean principles to show a measurable improvement in process performance.

- Company leaders agree to support the project teams by providing resources or time, people, and materials, removing barriers to project success.

|

|

|

“Working with Cedro has been incredible! My team has made significant improvements to our employee and patient satisfaction.” – Scott Rounds, MWMC

|

About Lean Six Sigma Toolbox

At Lean Six Sigma Toolbox, we believe that Continuous Improvement is the key to success and the primary differentiator between companies and teams who lead in their industry and those who fall behind. We help teams visualize their performance, identify gaps, and solve problems in a simple structured way. By teaching foundational Lean principles like the 8 Wastes and Kaizen (Continuous Improvement) System teams can quickly learn and adopt Lean tools and see measurable results.

We focus first on People, then on Processes, which leads to improved Performance.

Results

Our proven GEAR methodology has enabled Fortune 100 companies and small businesses alike to lower costs, increase customer satisfaction and drive significant business results like the ones below.

- Reduced lead times for Tesla components by 80%

- Improved throughput of mattresses at Purple mattress by 3.3X

- Eliminated lost parts and unnecessary reorders at MityLite

- Improved quality and durability of military hiking boots at Wolverine by 68%

- Improved throughput at Mountain West Medical Center’s ED by 17%

Incredible Clients – Incredible People

Over 100 clients on 5 continents trust Lean Six Sigma Toolbox to help them streamline processes, improve quality, and deliver world class customer satisfaction. Leverage our expertise to amplify your culture of Continuous Improvement and reach your goals. Here are a few clients you may be familiar with.

Cedro Toro Cedro ToroPresident Lean Six Sigma Toolbox· Certified Lean Six Sigma Master Black Belt, Project Management Professional· Lean coach and trainer for Fortune 500 companies, Walmart, Tesla, Micron and Consumer Reports helping them add millions to their bottom line· Entrepreneur with 3 startups and 2 exits including KPI Fire in 2021· Received Manufacturer of the Year award from Utah Manufacturers Association while VP of Manufacturing at Purple mattress· Holds an MBA from Idaho State University and Bachelor of Science in Electrical Engineering from the University of Utah. |

For more information visit or contact us at:

801.900.6050

Our team at Lean Six Sigma Toolbox looks forward to working with you to achieve your goals.

Related products

Online Training

Online Training

Online Training

Kaizen Idea Cards

Kaizen Idea Cards